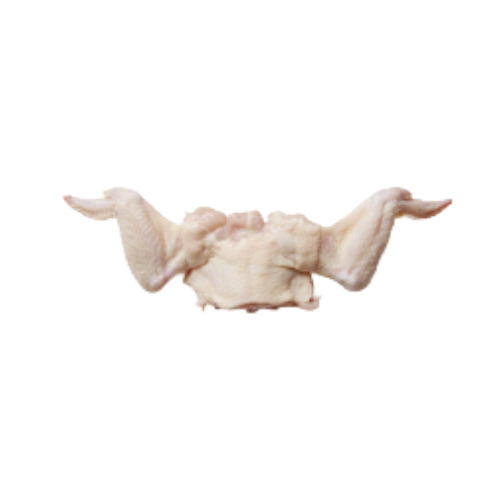

designed for: Cutting up a whole bird into 10 different pieces

Capacity: up to 2500 birds per hour

Advantages:

designed for: Cutting up a whole bird into 10 different pieces

Capacity: up to 2500 birds per hour

Advantages:

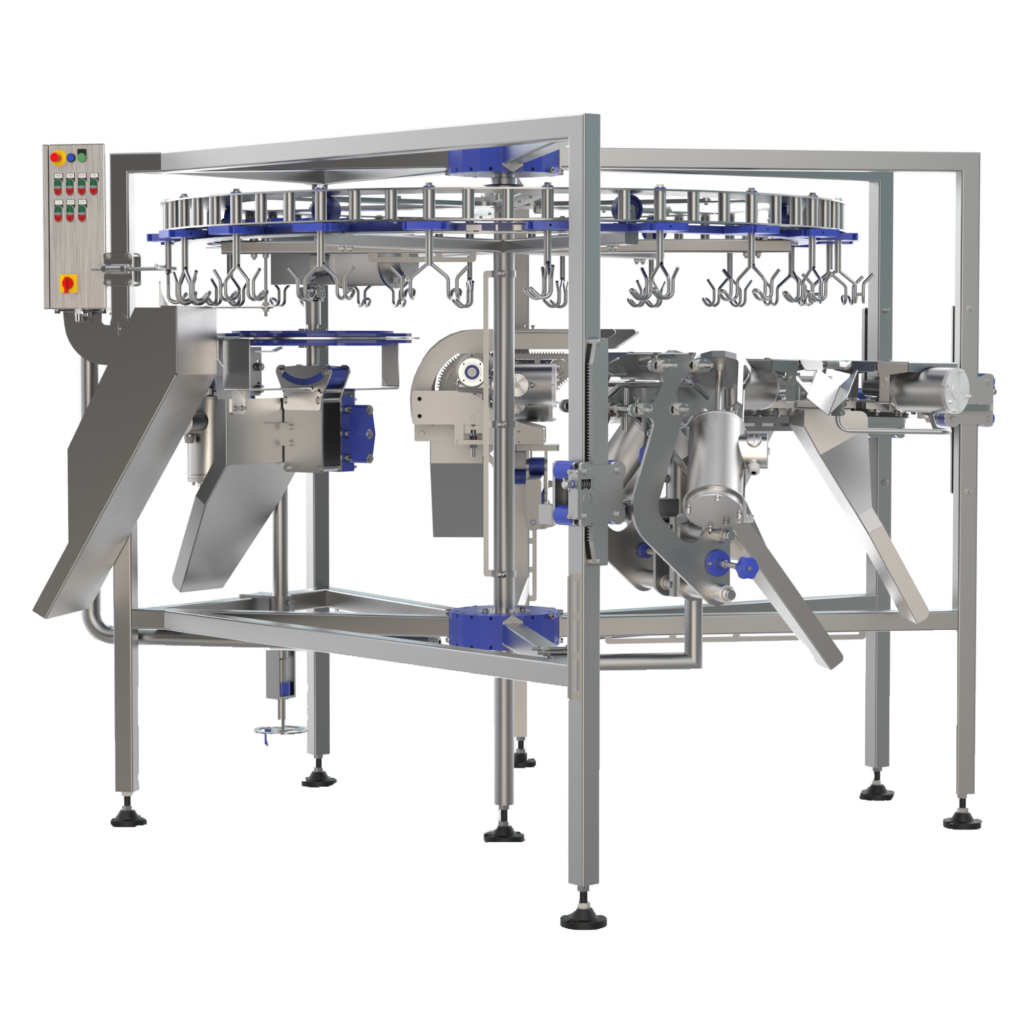

The Automatic Circular Cut-Up Machine is a high-efficiency poultry processing solution designed for accurate and consistent portioning in a compact layout. This automatic cut-up system is ideal for poultry processors looking to increase capacity while maintaining product quality and reducing labor costs. Engineered in the Netherlands, the machine combines reliable performance with ease of use and low maintenance.

With a processing capacity from 500 up to 3,500 birds per hour, depending on configuration, the CCM offers flexible cutting options and easy integration with other poultry processing equipment. Its space-saving design, fast installation and hygienic open construction make it a smart investment for modern poultry processing plants.

Dutch Poultry Tech’s Circular Cut-up Machine (CCM)

| Model | Article | Per hour | Length | Width | Height | Weight | Installed power | Weight (packed) |

|---|---|---|---|---|---|---|---|---|

| CCM | Circular Cut-up Machine | up to 2500 | 2500 mm | 2500 mm | 2000 mm | 2000 kg | Depends on modulers | 2200 kg |

Discover our advanced configurations for poultry cutting solutions, designed to optimize your production efficiency. Our offerings include:

In today’s fast-growing poultry processing industry, flexibility and efficiency are key. Automating the cut-up department can offer a wide range of benefits that can add value to your business in a constantly changing market. Here is why you should integrate this technology:

The Poultry industry is a dynamic market where your customer demands are changing rapidly. The Circular Cut-up Machine provides the flexibility to change quickly. For example, changing your Circular cut-up machine from one product to another product or weight range can be done in less than 30 seconds per module. This adaptability allows you to stay competitive and respond effectively to market trends. Meeting your customer needs without compromising on efficiency and quality.

By streamlining your operation with the circular cut-up machine, you can significantly reduce the time and labor required for cut-up. By using automatic conveyor belts, there will always be a good streamlined flow within your facility. With upgraded speed and precision you can boost your overall production capacity, allowing for a higher output in less time!

Our automatic cut-up system ensures uniformity in cuts, which leads to consistent product quality. To ensure the highest yield, we advise you to use an automatic weighing system to ensure the closest possible weight range for the highest yield. Automatic Precision and standardization of the product minimize the risk of human error, which improves food and worker safety.

By Automating repetitive, labor-intensive tasks, you can reduce your reliance on manual labor. This not only lowers labor costs but also minimizes the challenges of workforce shortages in the industry. Investing in automation can lead to long-term savings and a more efficient workforce

Our automatic cut-up systems are designed to be user-friendly and require minimal maintenance. This simplicity allows your team to focus on production rather than troubleshooting machinery, ultimately enhancing overall operational efficiency, your employees will also be happy.

Dutch Poultry Tech has many videos available on YouTube demonstrating it’s machines.

The Compact Automatic Cut-Up Line from Dutch Poultry Tech is a versatile solution for efficient poultry cutting and portioning, capable of processing 500 up to 3,500 birds per hour depending on configuration and hangers. Designed with a compact footprint and easy integration, this automatic cut-up line supports a wide range of cuts including wings, breast, leg quarters, and drum/thigh portions while maintaining consistent quality and throughput. Built for simplicity in installation, operation, and maintenance, the system fits seamlessly into any modern poultry processing setup, helping processors boost productivity and maximize sellable product.

Dutch Poultry Tech is a leading innovator in poultry processing solutions, offering advanced machinery designed for efficiency, safety, and high-quality output. With decades of experience, Dutch Poultry Tech provides complete solutions, including deboners, cut-up systems, and full poultry processing lines. Their equipment is trusted worldwide by poultry processors seeking reliable, ergonomic, and high-performance machinery. From design to delivery, Dutch Poultry Tech ensures your poultry processing line operates smoothly, efficiently, and consistently.