designed for: Separates, cleans, and peels gizzards in one continuous operation.

Capacity: Up to 6000 gizzards per hour

Advantages:

designed for: Separates, cleans, and peels gizzards in one continuous operation.

Capacity: Up to 6000 gizzards per hour

Advantages:

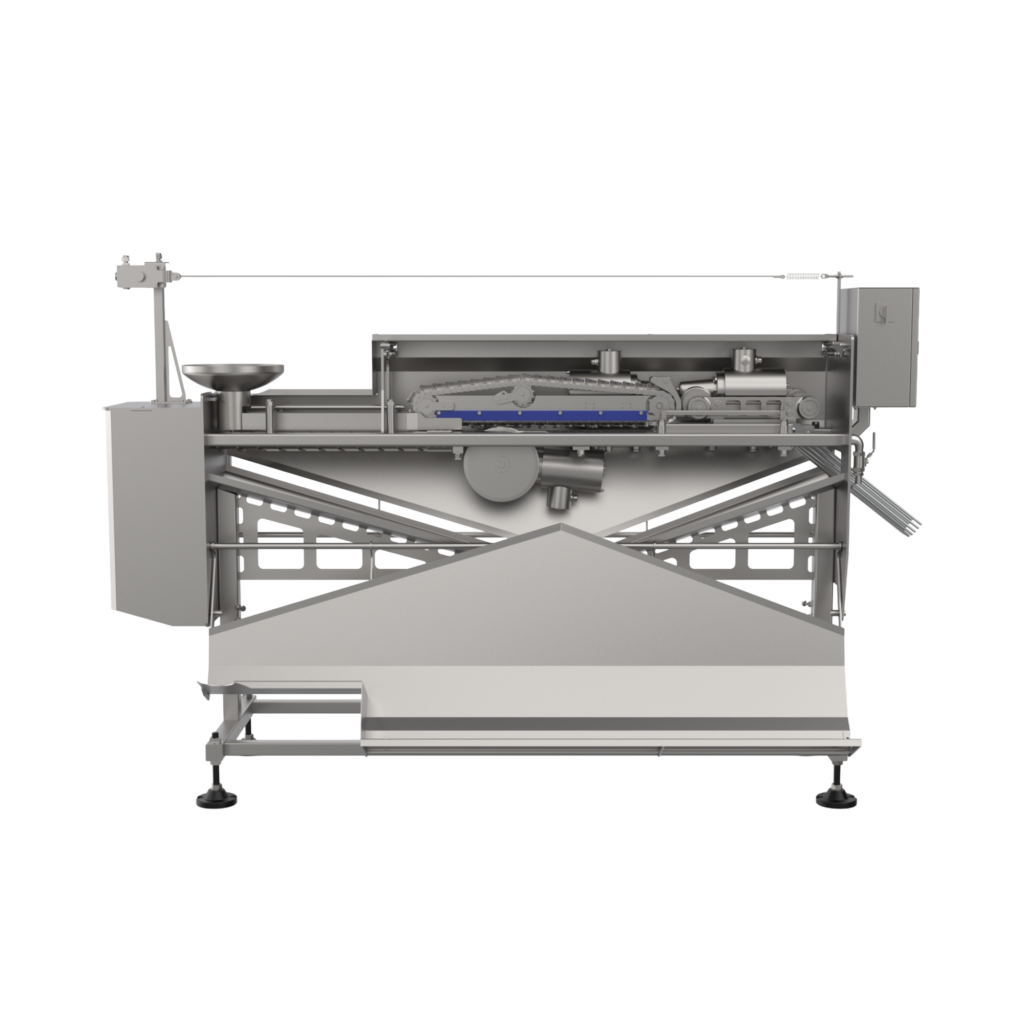

The Gizzard Harvester is an automatic poultry processing machine designed to separate, clean, and peel gizzards efficiently and hygienically. Engineered for modern poultry processors, it delivers consistent, high-quality gizzards while reducing manual labor. With a capacity of up to 6,000 gizzards per hour, the Gizzard Harvester streamlines giblet processing and integrates easily into evisceration lines, ensuring smooth workflow and optimal product quality.

Dutch Poultry Tech’s Gizzard Harvester (GOP-6000)

| Model | Article | Per hour | Length | Width | Height | Weight | Installed power | Weight (packed) |

|---|---|---|---|---|---|---|---|---|

| GOP-6000 | Gizzard Harvester | 6000 | 2100 mm | 600 mm | 1550 mm | 330 | 4 motors of 0.75 kW | 500 kg |

The Gizzard Harvester is a high-performance poultry processing machine designed to automate the separation, cleaning, opening, and peeling of gizzards immediately after evisceration. Engineered for modern processing plants, it delivers clean, peeled gizzards ready for inspection or further processing, reducing manual labor and improving overall workflow efficiency.

This advanced machine processes up to 6,000 gizzards per hour, achieving a 100 : 100 yield from gizzard in to gizzard out, with around 80 % of gizzards fully peeled, while the remainder can be refined at the inspection table. It operates using a minimum water pressure of 4 bar and consumes approximately 1.5 m³ of water per hour, ensuring thorough cleaning and rinsing during the peeling process.

High Throughput & Yield: Processes up to 6,000 gizzards per hour with excellent yield and consistent quality.

Automated Multi-Step Processing: Separates, opens, washes, and peels gizzards in one continuous operation.

Water-Cleaned Transport: Integrated water spray pipes clean the transport rolls and flush the gizzard contents efficiently.

Durable & Hygienic Design: Constructed from stainless steel and food-safe materials for long-lasting performance and easy cleaning.

Smooth Integration: Cleaned and peeled gizzards are discharged for inspection or further processing, fitting seamlessly into evisceration lines.

The Gizzard Harvester is ideal for poultry processors looking to maximize giblet recovery, improve processing efficiency, and maintain high hygiene standards. Its robust design and reliable performance make it an essential component in modern poultry evisceration operations.

Dutch Poultry Tech has many videos available on YouTube demonstrating it’s machines.

The Gizzard Harvester from Dutch Poultry Tech is an effective solution for poultry evisceration by‑product processing, designed to separate, open, clean, and peel gizzards automatically for hygienic, sellable results. This machine processes up to 6,000 gizzards per hour, delivering clean, peeled gizzards ready for inspection or further handling. With a robust design, reliable operation, and optional inspection tables for quality control, the Dutch Poultry Tech Gizzard Harvester helps poultry processors optimize giblet yield and streamline workflow.

Dutch Poultry Tech is a leading innovator in poultry processing solutions, offering advanced machinery designed for efficiency, safety, and high-quality output. With decades of experience, Dutch Poultry Tech provides complete solutions, including deboners, cut-up systems, and full poultry processing lines. Their equipment is trusted worldwide by poultry processors seeking reliable, ergonomic, and high-performance machinery. From design to delivery, Dutch Poultry Tech ensures your poultry processing line operates smoothly, efficiently, and consistently.